Products

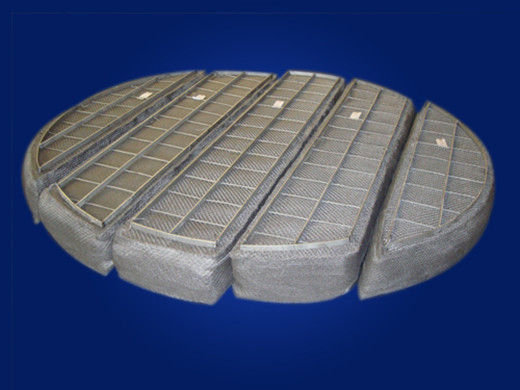

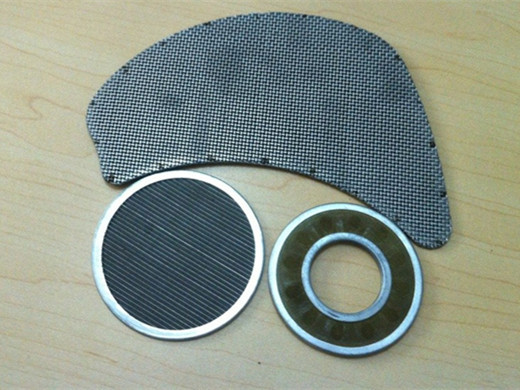

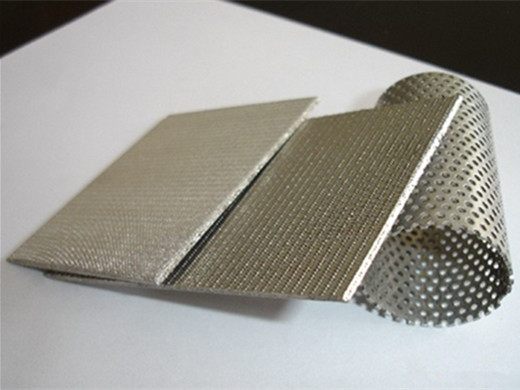

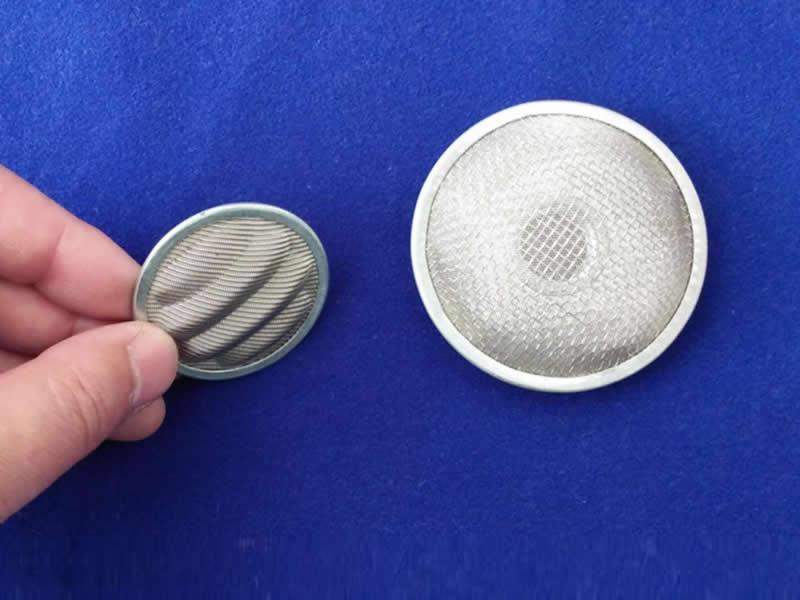

Demister Pad

Demister Pad also know as mist eliminator or spray. This is a kind of high efficiency separation devices,used throughout all kinds of process industries,to remove liquid droplets from gas or vapor streams.

Materials for making of demister filters cover stainless steel wire, copper wire,Monel wire, fiber glass and other fine materials. Demisters are classified into Standard Type, High Efficiency Type, High Permeability Type and Shock Absorption Type according to the features of filters.

Uses

Demister Pads – Mist Eliminators – Mist Separators widely used in following:

Absorber/Knockout Drum/Distillation Column/Extraction Column/Drying Towder/ Reactor/Flash Tower/Reboiler/Evaporator/Vacuum Tower/Prilling Tower/ Scrubber Gas Turbine/Steam Drum

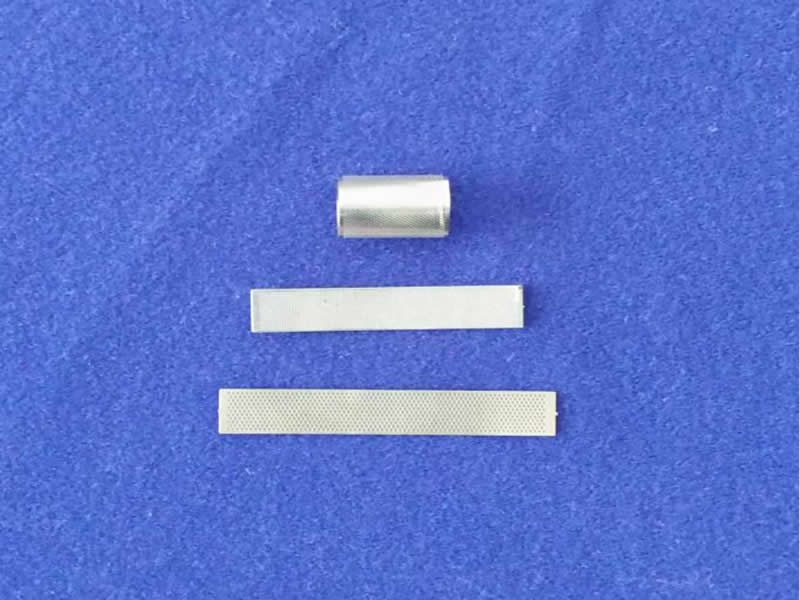

Standard Type Demister Pad

Common Diameter: 0.20 – 0.45mm

Weight Density: 168 Kgs/M3

Specific Surface Area: 529.6M2/M3

Porosity: 0.9788ε

High Efficient Demister Pad

Common Diameter: 0.12 – 0.45mm

Weight Density: 128 Kgs/M3

Specific Surface Area: 403.5 M2/M3

Porosity: 0.9839ε

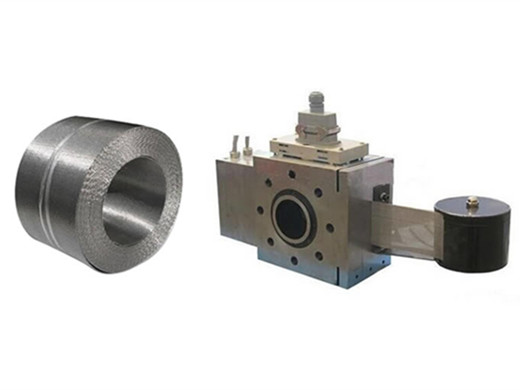

High Permeability Demister Pad

Specification List of Knitted Mesh | ||||

Model | Specification | Wire Diameter mm | Materials | Area/Weight M2/Kg |

High Permeability Model | 30-100 Model 30-150 Model 70-400 Model | 0.1 x 0.4 0.1 x 0.4 0.1 x 0.4 | Stainless Steel Wire Stainless Steel Wire Stainless Steel Wire | 1/0.4 1/0.4 1/0.4 |

Shock Absorption Type Demister Pad

Common Diameter: 0.21mm

Weight Density: 168 Kg/m3

Specific Surface Area: 529.6 m2/m3

Porosity: 0.9788ε

Advantages

High Efficienty High Turndown Ratio Light Weight Easy to Install No Operating Cost

No Moving Parts/Maintenance Low Pressure Drop